Bruce Valley School Restoration, 2019–2021

The Bruce Valley School was built in 1926 and served as a school until the 1960s at which point it was auctioned off and lived in as a residence periodically up to the present, changing owners several times.

I purchased the property at an in-person estate auction in September 2019 with the intention of establishing a studio. I moved in in early October and began restoration work.

Moving in. October 2019

The basement where I envisioned having a studio. In progress repairing the rotted floors. November 2019

The main room of the schoolhouse with east facing windows. Bed placed near the woodstove.

Looking over the valley. December 2019.

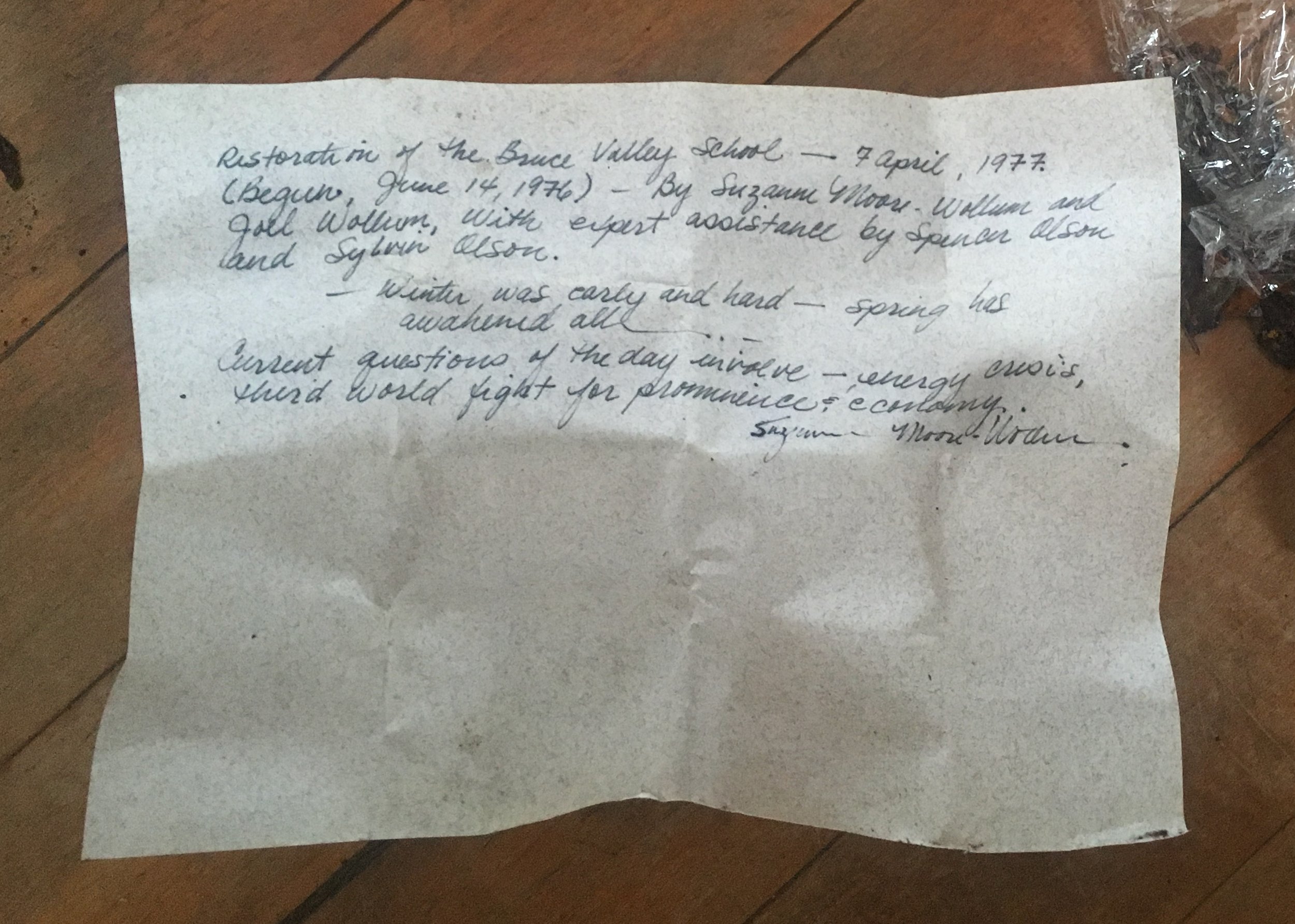

A note I found under the basement floor. “Winter was early and hard - spring has awakened all”.

Living there in the winter was cold. In January I got a job as a waiter in the nearest city and began working both to make money and to be somewhere warm. And to be around other people. That went well until I was laid off in March due to the Covid 19 pandemic. It was a cold and isolating winter but spring did come. I returned to waiting tables in May with a bump in hourly wage to $13 per hour plus tips due to Paycheck Protection Program money. That lasted for a time until it went back down to the legal minimum of $2.33/hr plus tips.

With mortgage payments of $361 per month, my bills were fairly low. I also lived quite frugally. I was putting most of my earnings into work on the house while managing to save some as well. I realized early on (within the first few weeks) that the project would likely not work long term. There were a handful of problems. First, heating the place in the winter was not easy and never would be unless I had a lot of money to put into improving the house (which I didn’t). Second, I was alone and too isolated. Third, being a waiter was actually fine in many ways but it was not a long term career prospect and I realized restoring the house on a shoestring budget was making progress both very slow and limited in scope.

Morning light. May 2020.

Dark skies in May 2020.

The summer was spent waiting tables and restoring the basement windows.

Restoring basement windows. Summer 2020.

Reglazing windows - using pumice to clean glazing residue off the glass.

It was a beautiful place to live. If there were no cars going by (and there often weren’t), I could speak at normal volume across the valley and hear my echo return clearly. At night, you could feel the cold air settle into the valley and a fog would sometimes roll in. On a clear night with a new moon you could see the Milky Way. Between the stars and the fog and the moon, the words astral and spectral often sat in my mind as apt descriptors.

View from the driveway looking southwest towards the Bruce Valley Church. August 2020.

View from the driveway looking southeast. August 2020.

September 2020.

As summer turned to fall and the weather started to cool, I built a loft in the bathroom to prepare for another winter. The bathroom was the only room in the building that was truly enclosed, so I figured I would be able to keep it moderately warm using a space heater - affording myself more comfort.

I built a loft in the bathroom to have a cozy place to sleep for the winter.

With winter's approach, I decided I would try to work as much as possible to save money and to avoid being stuck cold in my house. I got a seasonal job at a cheese factory in Fall Creek, Wisconsin. The factory usually runs two 12 hour shifts but for the holiday season to meet demand they added a 10 hour shift from 3pm - 1am. I worked Monday through Thursday and often added an overtime shift on Sundays. Fridays and Saturdays I worked closing at the restaurant, at times picking up earlier shifts to work doubles. Nights I spent sleeping in the loft. That winter I kept the house thermostat set to 40F. The house had a forced air furnace but using it felt like burning money because the heat left about as quickly as it entered and the price of LP had gone up significantly during the pandemic. So I kept the house at 40F to keep the pipes from freezing. When I was home I would make a fire in the wood stove and get the main room into the 60s or 70s. At night, the space heater in the bathroom/bedroom kept that room in the mid 50s. I slept very well at that temperature; I used a hot water bottle in the bed near my feet.

Schuman Cheese in Fall Creek, Wisconsin

At the cheese factory I was part of an operation to cut cheese and place it on to printed boards which were then vacuum sealed and packed into boxes to be sent to Costcos around the country and internationally. I was not allowed to take photos of the inside of the factory so I will share with you in words the oddness I encountered within.

The actual room where I spent the majority of my time was a large white box. I would guess it was 40’ x 60’ with 20’ ceilings. To enter this room you had to wear company provided rubber boots, a full length white lab coat, hair net, mask, and gloves. It’s a sanitary environment where large volumes of cheese are being handled. The temperature is about 40F so you have to dress warm under the lab coat. For me that meant long underwear, jeans, wool undershirt, knit wool shirt, wool sweater, and a company provided knit hat. Warm socks too.

The first day on the job, the batch of new recruits I was with were all herded into the above mentioned room, one side of which is occupied by a loud vacuum sealing machine (think large stainless steel box) with a conveyor belt of cheese boards moving through it, to be instructed by the floor manager. This is a man with thick glasses and a grizzled mug who I fear has worked too many years in the cheese factory - he barks out incomprehensible instructions in less than a minute and goes back to yelling at people and trying to make sure the vacuum sealer doesn’t stop. The vacuum sealer appears to be the heart of this operation - every cheese board must pass through it. If it breaks down, the cheese boards pile up and everything grinds to a halt.

The room itself, beside the vacuum sealer, is occupied by stainless steel tables where other workers are standing individually with a digital scale, a stack of printed boards, and five trays of cheese forming a semi-circle around them. The floor is covered in crumbles of cheese that have been stepped on and stood upon for the past however many hours to form an anti-fatigue mat of sorts. The smell of cheese is thick in the air. My first thought is to ask myself what layer of hell I have found myself in. But instead I ask one of the other workers what to do and it becomes clear fairly quickly - find a spot, get the five different types of cheese, and start assembling the boards.

The Kirkland Signature cheese flight, all the cheeses of which I know intimately.

The cheeses each have to be in the proper position and orientation and the net weight of the cheese on the board has to fall within the correct range. I quickly became adept at selecting the right slice of cheese in relation to the others to reach the correct weight. It was a game of sorts but one I realized I could not do for 50 hours a week for the next two months.

Thankfully there was another room attached to the main one accessible through a door on either side of one of the walls. On my second day, I ventured in. This was the cheese cutting room.

First I should clarify something. No cheese is made at this factory - it is only cutting and packaging cheese. One half of the factory (not related to this story) was dedicated to packaging individual servings of cheese and nuts in a little plastic container with the plastic seal that you peal off. The other half was for cutting cheese and placing it on boards to be vacuum sealed and sent to Costcos literally around the world.

The cutting room was where I realized I wanted to be. There were several types of machines - all stainless steel and apparently made in Italy, “costing a million dollars each” I was told. They cut the cheese systematically. One machine would clasp a full wheel of cheese horizontally between two hydraulic pistons that rotated the wheel as a wire was slowly pulled through it, producing two half wheels. These would then be put onto another machine that weighed the cheese and automatically cut slices to the correct weight.

It was all only so interesting but there were some characters who worked there. The only criteria as far as I could tell was to pass a drug test when hired and then to show up for work. At $17.00 per hour it was not a bad job for the area. Especially with the overtime. The work was basically mindless, but not quite - and between chatting with some friends I made and switching between different tasks, the time passed fairly quickly.

There would reach a time every night when all the cheese that was going to be cut and packed for the day was cut and packed and it was time to clean up so the next shift could begin again. That involved changing into yellow water proof bibs and jackets, spraying everything down into large drains in the floor, scraping the embedded cheese off the floor with large plastic scrapers, and generally goofing off within reason. Then every surface was sprayed with soapy foam, scrubbed down, rinsed off, sanitized, and swabbed to test for bacteria. If everything checked out, the room was left to dry and cool back down before the cheese was brought out so everything could begin again. Keep in mind, this factory runs 24 hours a day, 365 days a year. Right now as you read this (unless something has happened in the intervening years from when I was there), people are working in that cheese factory cutting and packaging cheese and nuts. Everything comes from somewhere.

The holidays came and went and shortly thereafter all temp employees were laid off. My tenure at Schuman Cheese was over.

Hoarfrost, January 2021.

Hoarfrost, January 2021.

This story is almost concluded.

In early February there was a stretch of several days forecasted to have daily low temperatures of -20F. Nothing filled me with more dread than the thought of being home for that time. I booked a ticket to Miami Beach with a couple of friends from work ($50 round trip flight). This was still very much pandemic times, yet the hostel where we stayed had a surprisingly international crowd. In a cliche way, being in the sun and having some fun reminded me that life doesn’t have to be so miserable.

I got back from Miami on a Thursday night, waited tables that Friday, Saturday, and all day Sunday. I got home from work Sunday around midnight to find ice forming in the dishes of my sink. I soon realized that the furnace had stopped working. For the next hour and a half I tried to troubleshoot the furnace to get it running. The temperature outside was -15F; in the house it was about 32F and dropping. The pipes were starting to freeze.

After realizing I was unable to get the furnace working I made a large fire in the main floor wood stove to keep the temperature up over night. I went to bed around 3am.

I woke up to the pipes being more frozen though not burst. Outside temperature was -20F. I built and maintained large fires in both the main floor and the basement wood stoves as well as ran a space heater and a heat lamp in the utility room all in an effort to thaw the pipes so that I could drain them.

It was a desperate effort and at the time I thought it had worked as I was able to get a lot of water out of the pipes. I packed up everything I didn’t want to freeze and made a strategic retreat to my parents house 2 hours away in Saint Paul, MN. Two days later I decided I would move to New York City. I bought tickets for the following week. I worked a couple last shifts at the restaurant and told them I may be back in a month or so if things don’t work out.

Headed to New York. February 2021

In my bags I packed a pot and a cast iron skillet with one pound each of brown rice and steel cut oats. I did not know what I was going to encounter in NYC.

I booked an Airbnb for a week - the cheapest place I could find. From there I found a month long sublet and started applying to jobs. From there I found a job and another sublet and from there a good job and a more permanent place to live.

It was an interesting time to move to New York. Before moving I had the feeling it was as good an opportunity as ever. I knew the city suffered tremendously during the pandemic and I figured many things were in flux. If there was ever an opening, I thought that might be it. I was also 29 years old and I could tell the schoolhouse project was largely going nowhere. I felt I had nothing to lose besides perhaps a few thousand dollars (which thankfully I had saved from working those long hours at the cheese factory).

So I slowly found stability in New York and I decided I would sell the schoolhouse. That summer I was able to go back to Wisconsin for a few stretches of time to finish the work that I had started and to make it sellable. There was a real sense of urgency to get it listed before winter- never had I worked so hard or been so stressed- but it was good and fun in it’s own way. I sold the house and actually made some money. The following April, just more than a year after moving to New York, I rented a commercial space and began building what has become Flatbush Clay Works.